The S2000LP binding machine boasts a robust and feature-rich design tailored for precision and efficiency in glue-binding applications.It combines a solid steel frame structure with advanced features, making it suitable for a diverse range of materials. Its precision milling, 180-degree spine opening, and use of PUR hot melt glue ensure high-quality and durable bindings. The intelligent control, LCD display, and user-friendly design further contribute to efficient and seamless operation.

The intelligent features of the HJ S2000LP help increase efficiency and productivity in the binding process. The combination of automated features simplifies operations and improves overall throughput. Designed with user-friendliness in mind, the machine offers intuitive controls and features that simplify the binding process. This ensures a great user experience and promotes efficient machine operation.

1.Industry-leading design, many patents

of glue spraying invention

Perfect back glue, side glue structure design hold naonal invenon patents on many spray-glue technology.

2.Solid steel frame structure design

Full solid steel frame structure hard to be distorted.

3.Aluminum casting carrier, stable and

prolong durable

Aluminum casng carrier and large volume of tank, more stable.

4.Hold patent on many technology patents

of new milling back slotting

24 small milling cuer wonderful binding effect for the coated paper, inner not easy to fall.

5.Hold patent on appearance

Integrated streamline appearance arc edge chamfering for safe

operaon convenient and simple suitable for digital fast prinitng office environment.

6.Intelligent control, 7” touch screen display ARM CORTEX M4 smart card

Powerful seng funcon. 7inch color capacive screen.

Intelligent interface and the safety inspection functions.

Specifications

| MODEL | PUR-S2000LP | |||

| Cover Dimension | Max. 700mm x 460mm ; Min. 230mm x 120mm | |||

| Book Height | Max. Width - 350mm ; Min. 120mm | |||

| Cover Weight | 110 - 400gsm | |||

| Speed | 200-300 books/h | |||

| Milling cutter mode | slotting cutter | |||

| Display | 7" Touch screen | |||

| Dust extraction | Yes | |||

| Spine Thickness | 2 mm - 60 mm | |||

| No. of clamp | 1 | |||

| Power | 220V / Single Phase, 50/60 Hz 3KW with AVR stablizer | |||

| Machine weight | 300KG | |||

| Machine measurement (LxDxH)mm | 1680x620x1450 | |||

Double straight line guide clamp system: digital transmission

• PUR melt cut off the supply of - nozzle spray system (it can use a system)

• (PUR melt supply-air shut-off nozzle spray method)

•Melting Tank Technology - Sealed Tank PUR Melter System

Competitive Advantage:

1.Solid Steel Frame Structure Design

The machine incorporates a solid steel frame structure, ensuring stability and durability. This design provides a robust foundation for the various components, contributing to the longevity of the equipment.

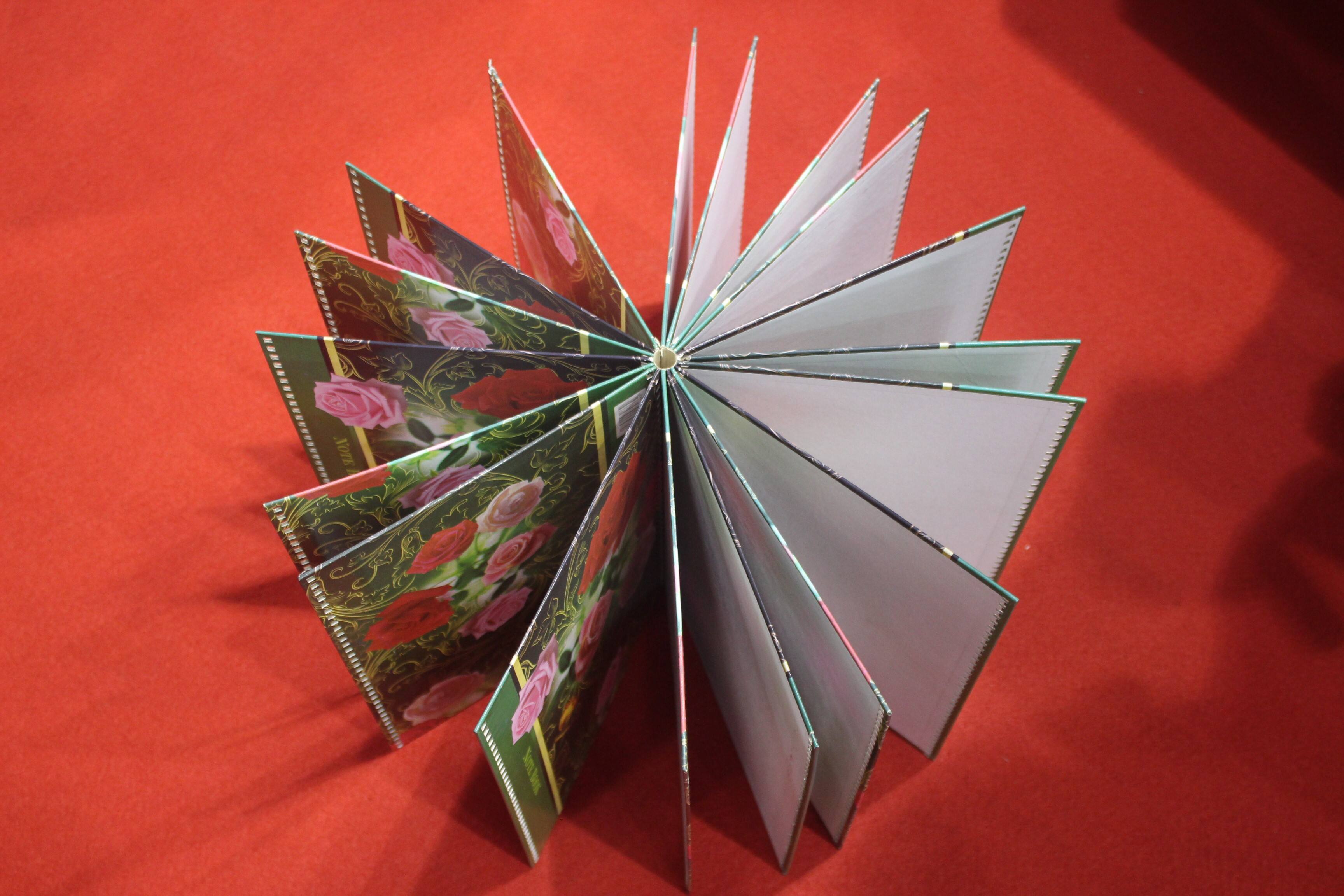

2.Versatility for Different Materials

Specifically designed to handle a variety of materials, including album material, coated paper, and thick book glue-binding. This versatility allows for a wide range of applications, making it suitable for diverse binding needs.

3.High-Power Milling Back with Tungsten Steel Sun Knives and sophisticated Milling and Notching Device

Features a high-power milling back equipped with 22 double-layer tungsten steel sun knives. This configuration enhances the precision of the milling process, contributing to the overall quality of the binding.

Incorporates a sophisticated milling and notching device for spine preparation. This ensures a precise and well-prepared spine, promoting a strong and durable binding result.

4.180-Degree Inner Book Spine Opening

After glue application, the machine allows the inner book spine to open at a 180-degree angle. This feature facilitates a flat layout, enabling books to be placed horizontally on a table for convenient handling or additional processes.

5.PUR Glue with Hot and Cold Resistance and intelligent Control and LCD Display

Utilizes PUR hot melt glue known for its hot and cold resistance. This type of glue ensures a reliable and durable bond that can withstand varying temperature conditions.Equipped with intelligent control features and an LCD display. This enhances user interaction, allowing for precise control of the binding process and providing real-time information on machine status.

6.Air Pump and Import Induced-Draft Device

Comes with an air pump and an imported induced-draft device. These components contribute to efficient dust removal during the binding process, maintaining a clean working environment.