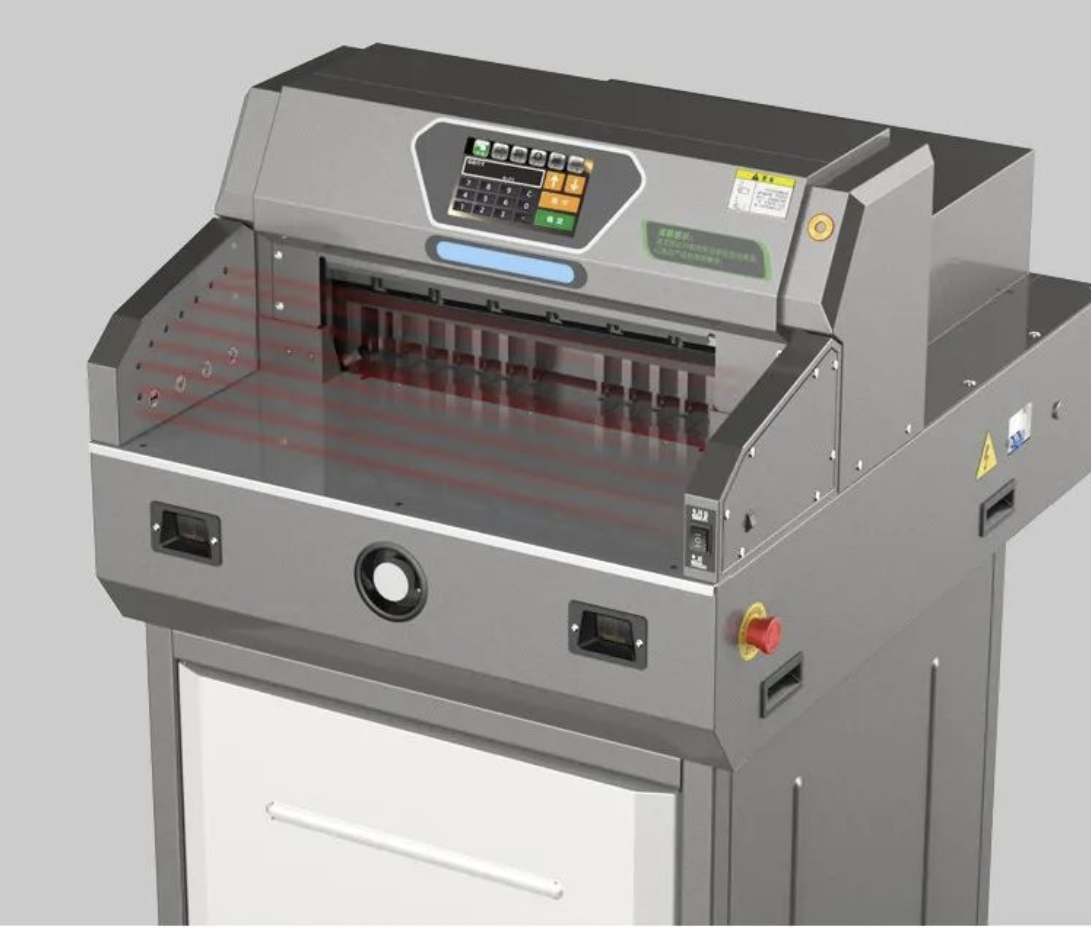

FRONT H498T is designed for high-volume use and is unquestionably a professional paper cutter, employing hydraulic blade and adjustable clamp driving systems. The hydraulic clamping and cutting enable efficient and effective cutting operations. Its infrared safety curtain is electronically controlled, ensuring complete safety during use. If anything breaches the safety curtain, the operation immediately stops. It allows for safe blade replacement and is equipped with a convenient and secure blade replacement device.

This professional paper cutter is more user-friendly than previous models due to the upgraded touchscreen panel, which is more convenient than the old standard keyboard control panel. The electronic programmable control module allows users to easily position the rear material stop. The improved touchscreen also features a large memory capacity, capable of storing 100 programs with up to 98 steps each. The touchscreen can store repetitive and frequent cutting actions. The H498T also comes with an electronic handwheel, ideal for manual positioning of the rear material stop, as it offers stepless speed control from very slow to very fast.

Specifications

| Item Model | FRONT H498T | FRONT H520TV7 | FRONT H670T7 |

| Max Cutting Size | 495*495mm19. 48*19. 48 inch | 520*520 mm | 670*670 mm |

| Max Cutting Thickness | 83mm/3. 26 inch | 80mm/3. 14 inch | 80mm/3. 14 inch |

| Min. Cutting Size | 30mm/1. 18 inch | 30mm/1. 18 inch | 30mm/1. 18 inch |

| Cutting Accuracy | ±0. 2 mm | ±0. 2 mm | ±0. 2 mm |

| Ball table | / | √ | √ |

| Desktop Material | Stainless Steel Desktop | Aerospace-Grade Aluminum Desktop | Aerospace-Grade Aluminum Desktop |

| Press Way | Hydraulic | Hydraulic | Hydraulic |

| +Pedal | +Pedal | +Pedal | |

| Cutting Way | Hydraulic | Hydraulic | Hydraulic |

| Display | 7" Touch Screen | 7" Touch Screen | 7" Touch Screen |

| Program | √ | √ | √ |

| Arithmetic | √ | √ | √ |

| Push Motor | Step motor | Step motor | Step motor |

| Frequency Conversion Motor | / | / | / |

| Electronic Knife Lock Structure | Optional | Optional | Optional |

| Power | 220V(110V)±10%, | 220V(110V)±10%, | 220V(110V)±10%, |

| 50Hz(60Hz), | 50Hz(60Hz), | 50Hz(60Hz), | |

| 1800W | 1950W | 2350W | |

| Side Table | / | Optional | Optional |

| Machine Size(mm) | 1280*980*1430 | 1280*1010*1430 | 1565x1030x1470 |

| N. W: | About 290KGS/639. 34 lb | About 320KGS/705. 47lb | About 460KGS/1014. 12lb |

Competitive Advantage:

1.7-INCH DIAGONAL TOUCHSCREEN

FRONT H498T features a 7-inch touchscreen.

Offering three different operating modes: manual, equal division, and programmable, meeting daily work requirements with easy switching and simple operation.

The user-friendly perspective makes the usage more comfortable and convenient.

2.MULTIPLE SAFETY PROTECTIONS

In order to comprehensively ensure safety measures, the machine is equipped with an air switch, power switch, emergency stop button, and a triple protection system, compliant with CE standards.

Furthermore, to ensure safety during the cutting process, the machine incorporates an infrared photoelectric safety protection design. If any foreign object approaches the operation table, the machine immediately halts its operation, providing additional safety assurance for operators.

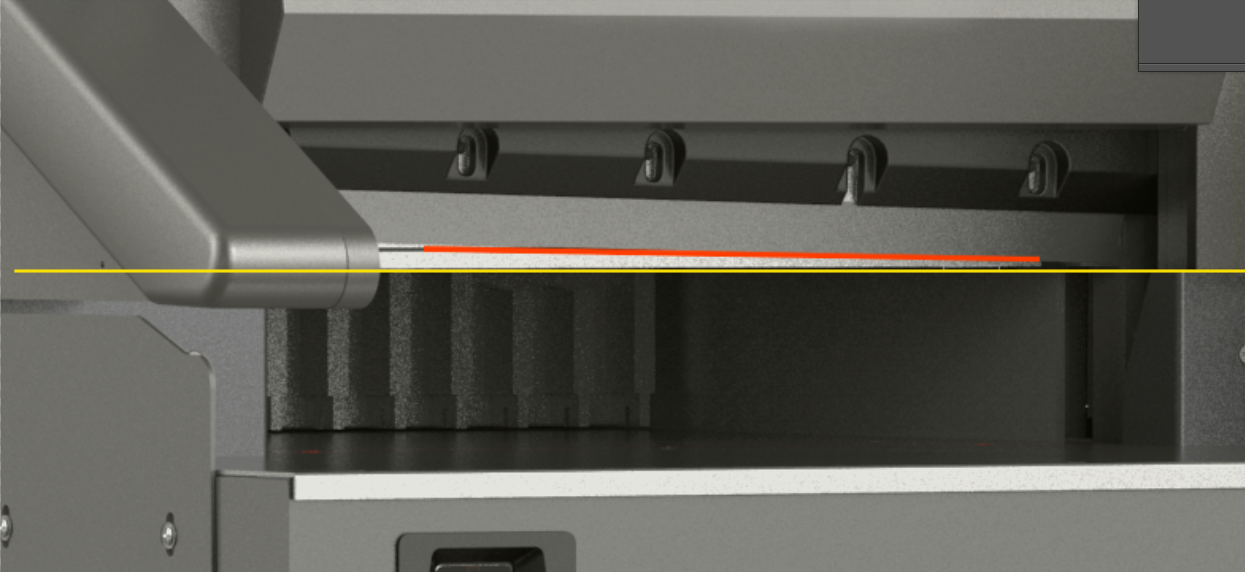

3.SLANTED BLADE PAPER CUTTING PATENT

Having obtained the utility model patent for slanted blade paper cutting (Utility Model Patent No.: ZL202021215296.6)

This innovative design enables easier cutting, particularly suitable for thick paper cutting. The cutting process is more efficient, ensuring precision and convenience, thereby providing users with a superior cutting experience.

4.TOP-SUSPENDED BALL SCREW PAPER PUSHING STRUCTURE

The paper pushing platform is designed without grooves, combined with the top-suspended screw paper pushing technology, achieving a more stable and smooth paper pushing operation.

This innovative design not only enhances the stability of the machine but also significantly improves the precision of the cutting process, ensuring accurate cutting results.

4.DOUBLE HYDRAULIC POWER CONTROL SYSTEM

Taiwanese main motor delivers strong power, while imported hydraulic valve components ensure machine quality. Both cutting pressure and paper pressing pressure can be adjusted according to cutting requirements.

5.ALLOY STAINLESS STEEL FRONT PLATFORM

Utilizing a platform made of 3mm thick alloy stainless steel, it is durable, aesthetically pleasing, and stylish. The choice of this material ensures its stability, making it a sturdy and reliable working platform.

6.ADDED MECHANICAL FOOT PEDAL

The addition of a mechanical foot pedal makes pre-positioning for cutting saddle-stitched books more convenient and enhances precision.

This feature allows operators to easily position for cutting saddle-stitched books, significantly improving overall cutting accuracy and precision.

7.Electronic Knife Lock Structure(Optional)

The advanced electronic knife lock structure effectively prevents the occurrence of slipping phenomenon during the cutting process and ensures safe operation.