FRONT CP6810L is equipped with a dual hydraulic powerful system, featuring a heavy-duty gantry structure and heavy-duty high-speed steel blade. It offers higher efficiency and durability, designed specifically for high-volume use. This professional paper cutter uses hydraulic blades and an adjustable clamp driving device. Hydraulic clamping and cutting technology ensure efficient and effective cutting, while a two-way oil cylinder guarantees a complete positioning of the blade after each cut.

The machine's infrared safety curtain is electronically controlled, ensuring safety during operation, immediately stopping if any object crosses the safety curtain. The blade replacement operation is also very safe, as the machine is equipped with a convenient and secure blade replacement device.

This professional paper cutter is easier to use than previous models, as the newly upgraded touch panel is more convenient than the old standard keyboard control panel. The electronic programmable control module allows users to easily position the back gauge. The improved touch panel has a large storage capacity, capable of storing 100 programs, each with a maximum of 98 steps.

The touch panel supports storage functions for repetitive and frequent cuts. Additionally, the machine is equipped with an electronic handwheel for manual positioning of the back gauge, featuring stepless speed control from very slow to very fast.

Specifications

| Item Model | FRONT CP5610L | FRONT CP6810L |

| Type | Aerospace-Grade Aluminum Desktop | Aerospace-Grade Aluminum Desktop |

| Max Cutting Size | 530*560mm20. 86*22. 04 inch | 680*680mm26. 77*26. 77 inch |

| Max Cutting Thickness | 100mm/3. 93inch | 100mm/3. 93inch |

| Min. Cutting Size | 30mm/1. 18inch | 30mm/1. 18inch |

| Cutting Accuracy (mm) | ±0. 2 | ±0. 2 |

| Ball table | √ | √ |

| Press Way | Hydraulic | Hydraulic+Pedal |

| +Pedal | +Pedal | |

| Cutting Way | Hydraulic | Hydraulic |

| Display | 10. 2"Touch Screen | 10. 2"Touch Screen |

| Program | 100Groups*96 Cuts | 100Groups*96 Cuts |

| Arithmetic | √ | √ |

| Push Motor | Medium-speed stepper motor | Servo motor |

| Frequency Conversion | √ | √ |

| Power | 220V±10%, | 220V±10%, |

| 50Hz(60Hz), | 50Hz(60Hz), | |

| 2500W | 2500W | |

| Machine Size(mm) | 1010*1320*1500mm | 1090*1410*1500mm |

| N. W: (Kg) | About450kgs | About530kgs |

Competitive Advantage:

1.10.2-INCH DIAGONAL TOUCHSCREEN

FRONT CP6810L features a 10.2-inch touchscreen.

Offering three different operating modes: manual, equal division, and programmable, meeting daily work requirements with easy switching and simple operation.

The user-friendly perspective makes the usage more comfortable and convenient.

2.VARIABLE FREQUENCY HYDRAULIC TECHNOLOGY

Variable Frequency Cutting Technology provides precise cutting, resolves depth inconsistencies, and enhances the lifespan of blades and cutting bars.

The variable frequency hydraulic system (380V to 220V) offers robust power, ensuring greater cutting force and improved stability.

It requires no replacement of centrifugal switches or capacitors, making post-maintenance much more convenient. With superlative silent technology, the cutting process remains noiseless, creating a quiet and harmonious office environment.

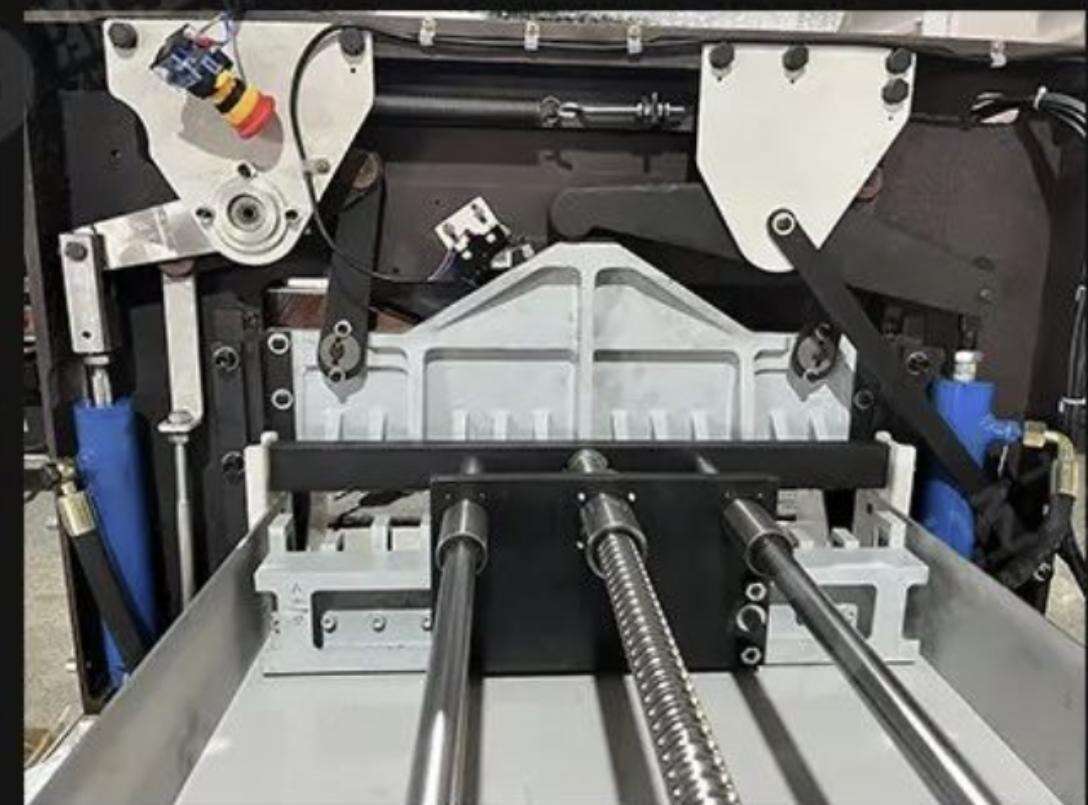

3.WHOLE CASTED BLADE HOLDER WITHOUT GROOVES DESIGN

The integral cast blade holder is designed without grooves, which prevents wear on the slide rails, leading to a longer lifespan.

4.MULTIPLE SAFETY PROTECTIONS

In order to comprehensively ensure safety measures, the machine is equipped with an air switch, power switch, emergency stop button, and a triple protection system, compliant with CE standards.

Furthermore, to ensure safety during the cutting process, the machine incorporates an infrared photoelectric safety protection design. If any foreign object approaches the operation table, the machine immediately halts its operation, providing additional safety assurance for operators.

5.SLANTED BLADE PAPER CUTTING PATENT

Having obtained the utility model patent for slanted blade paper cutting (Utility Model Patent No.: ZL202021215296.6)

This innovative design enables easier cutting, particularly suitable for thick paper cutting. The cutting process is more efficient, ensuring precision and convenience, thereby providing users with a superior cutting experience.

6.TOP-SUSPENDED BALL SCREW PAPER PUSHING STRUCTURE

The paper pushing platform is designed without grooves, combined with the top-suspended screw paper pushing technology, achieving a more stable and smooth paper pushing operation.

This innovative design not only enhances the stability of the machine but also significantly improves the precision of the cutting process, ensuring accurate cutting results.

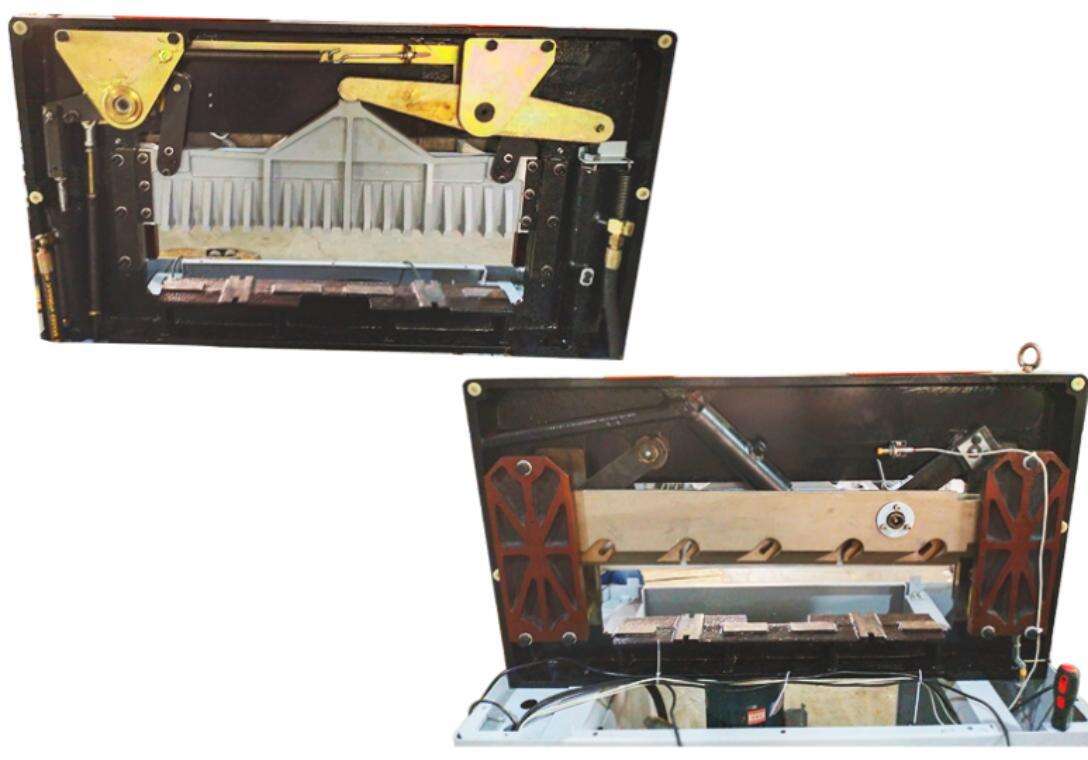

7.DOUBLE HYDRAULIC POWER CONTROL SYSTEM

Taiwanese main motor delivers strong power, while imported hydraulic valve components ensure machine quality. Both cutting pressure and paper pressing pressure can be adjusted according to cutting requirements.

8.12MM THICK HARD ALLOY ALUMINUM PLATFORM

Equipped with floating air bubbles and subjected to special processing techniques, it offers a solid, durable, and scratch-resistant feature. This treatment enhances the surface's abrasion resistance, making it more durable.

9.NEW UPGRADED SECOND-GENERATION DUAL-ACTION HYDRAULIC CYLINDER

Equipped with floating air bubbles, special process treatment, solid, durable, and scratch-resistant.

10.HEAVY-DUTY INTEGRAL CASTING STRUCTURE DESIGN

Heavy-duty cast frame design, precision machining process ensures cutting accuracy meets professional standards, and enhances durability

11.Electronic Knife Lock Structure(Optional)

The advanced electronic knife lock structure effectively prevents the occurrence of slipping phenomenon during the cutting process and ensures safe operation.