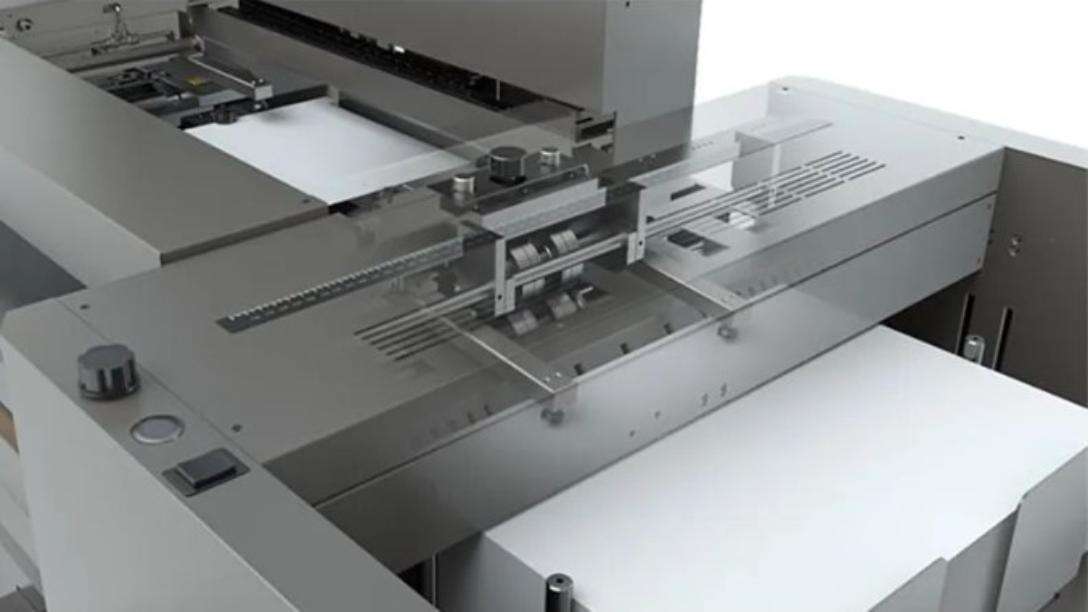

HJ H20L is a professional glue binding machine specially designed for large quantities for binding. It adopts a new intelligent indentation design, paper feed and four indentation synchronization, which is easy to use ,it saves manpower and improves the efficiency for book production. According to the thickness of the book,it can automatically measure the thickness and adjust the running speed of the machine,also it automatically adjust the pressure of the clip surface, so that it can obtain the best binding effect. This can greatly improve production efficiency and reduce the workload of the operator. High-precision binding ensures that each book has a uniform and firm binding connection, improving the quality and durability of the product. Industrial synchronous belt transmission structure, light sound, fast speed.At the same time, the machine also added the function that automatic finishing glue structure ,it can solve the glue problem left on the clamping surface platform effectively , meanwhile the binding looks more beautiful. It also added the function for cover secondary positioning technology, to solve the book cover position deviation problem, to ensure the cover left and right positioning accuracy.The new pre-melt groove structure allows the operator to add glue without stopping, improving the binding efficiency.

This automatic glue binding machine is more efficient, accurate, intelligent, longer life than other binders, and the plc integrated module control circuit design is more stable and reliable, which is loved by consumers.7 inch color touch screen display, using arm chip and color touch screen, powerful intelligent control program a number of self-test functions.

Specifications

| Item Model | HJ H10L | HJ H20L | HJ H300 |

| Type | A4Automatic Cover Feeder Creasing Glue Binder | A3Automatic Cover Feeder Creasing Glue Binder | AutomaticCover Feeder Creasing Glue Binder With Automatic Book Collection |

| Max Binding Length | Automatic120-330mmManual 425 mm | Automatic120-425 mm | Automatic120-320mm Manual 425 mm |

| Binding Thickness | 0. 2-60mm | 0. 2-60mm | 0. 2-60mm |

| Book Block Height | 135-297mm | 135-297mm | 135-297mm |

| Max Cover Binding Length | Automatic500mm*330mmManual 660*425mm | Automatic660mm*330mm | Automatic660mm*330mm |

| Cover thickness | 120-300g | 120-300g | 120-300g |

| Cover Feeder Capacity | 98mm | 98mm | 98mm |

| The cover indentation center positioning function | automatically adjusted | automatically adjusted | automatically adjusted |

| Cover indentation | Four indentation lines | Four indentation lines | Four indentation lines |

| Cover sidegauge | CNC adjustment | CNC adjustment | CNC adjustment |

| Cover side shot function | √(pneumatic) | √(pneumatic) | √(pneumatic) |

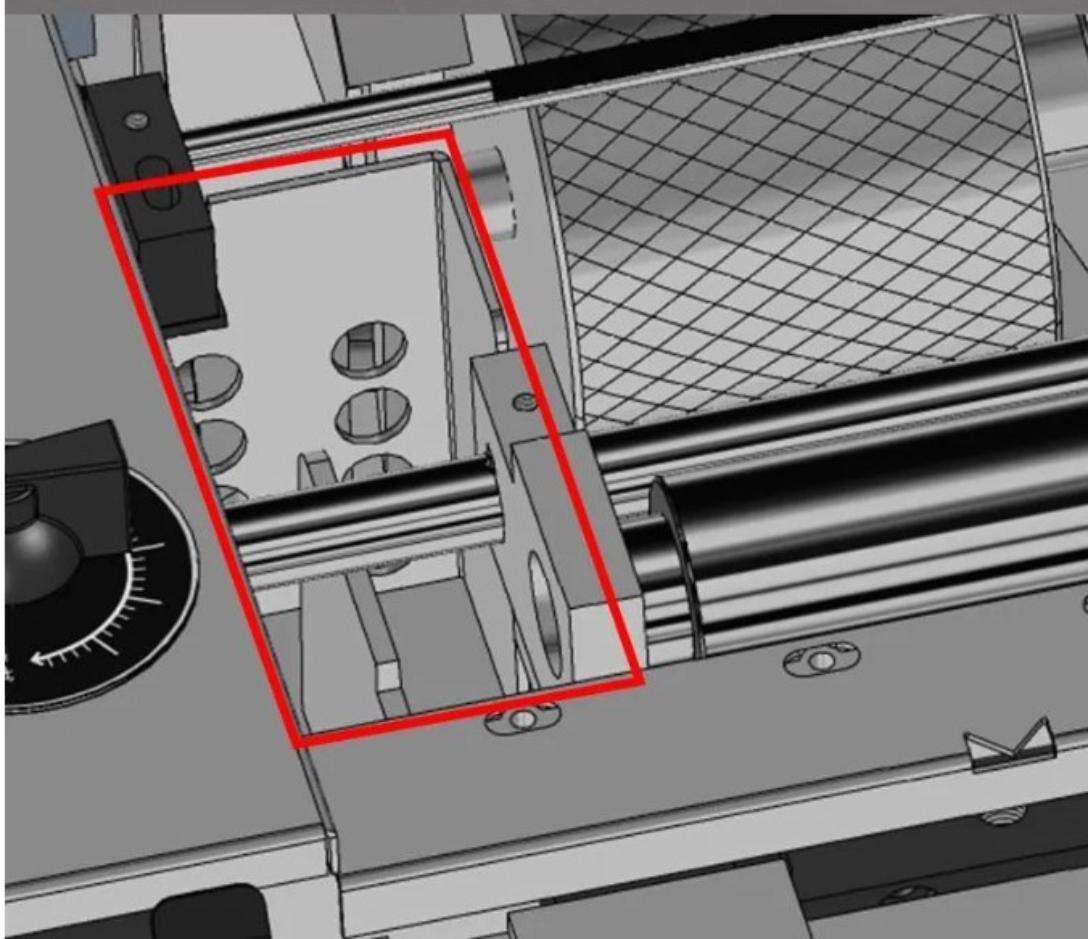

| Milling Cutter | 20Teeth large Disc Milling Cutter+2 Small milling cutters | 20Teeth large Disc Milling Cutter+2 Small milling cutters | 30Teeth large Disc Milling Cutter+4 Small milling cutters |

| Glue speed | 400-500books/hour | 400-500books/hour | 400-500books/hour |

| Heating Time | 45min | 45min | 45min |

| Automatic Measurement Of Book Thickness | √ | √ | √ |

| Gluing method | Single Rubber Wheel + Side Rubber +Rubber Roller | Single Rubber Wheel + Side Rubber +Rubber Roller | Single Rubber Wheel + Side Rubber +Rubber Roller |

| Pre Sol Tankstructure | √ | √ | √ |

| Automatic finishing glue | √ | √ | √ |

| Smoke Exhaust Function | √ | √ | √ |

| Height adjustment of Clamping Surface | Intelligent Adjustment | Intelligent Adjustment | Intelligent Adjustment |

| Side glue + milling cutter with pre-opening function | √ | √ | √ |

| Cover Secondary automatic positioning | √ | √ | √ |

| Book Collection | × | × | √ |

| Display | 7"Touch Screen | 7"Touch Screen | 10. 1"Touch Screen |

| Power | 220V±10%, | 220V±10%, | 220V±10%, |

| 50Hz(60Hz), | 50Hz(60Hz), | 50Hz(60Hz), | |

| 2600W | 4000W | 4000W | |

| Machine Size(mm) | 1985*710*1260 | 2228x820x1260 | 2200x970x1245 |

| N. W: (Kg) | About300KGS/ 661. 38lb | About320KGS/705. 48 lb | About550KGS / 1212. 54 lb |

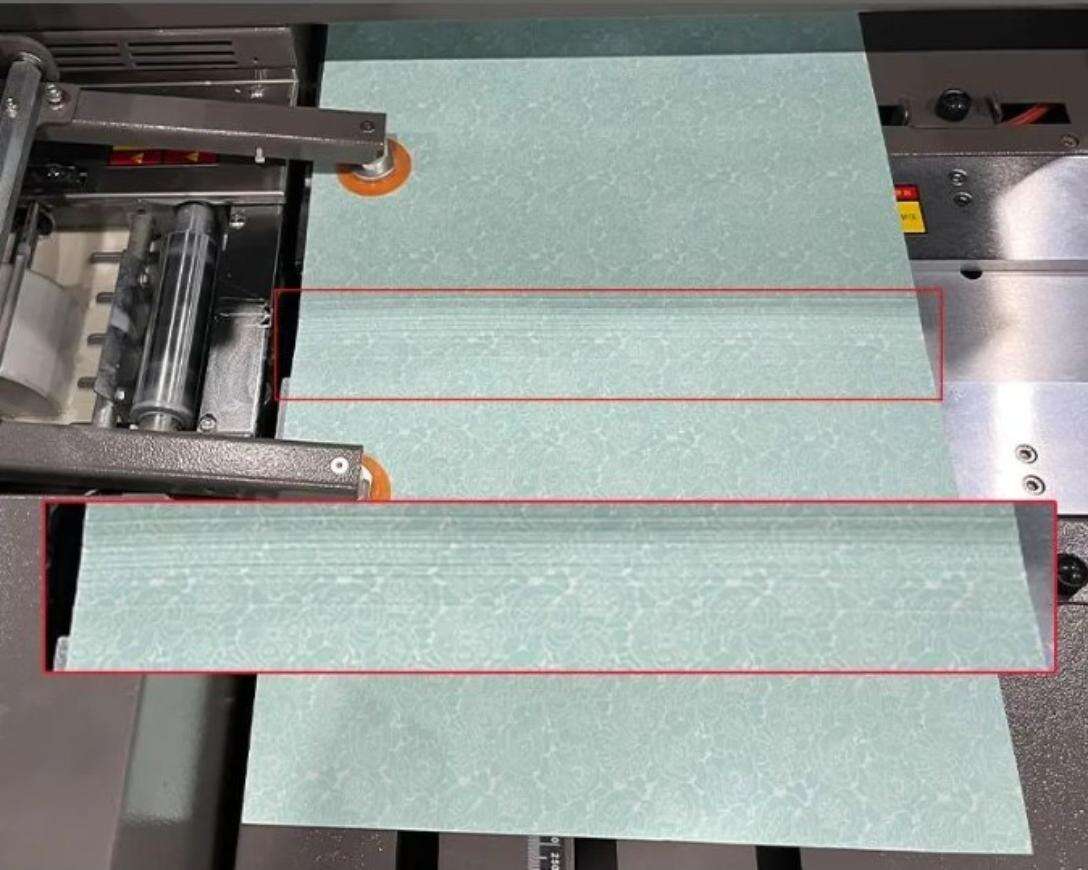

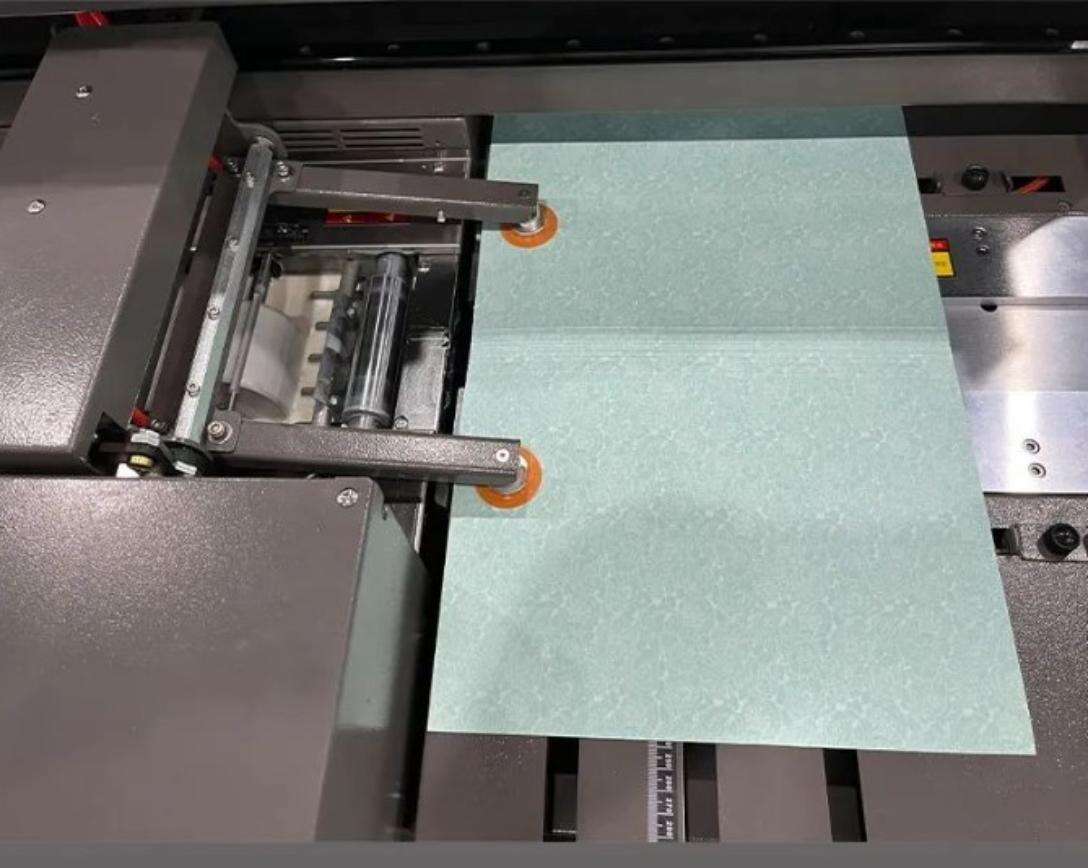

1.Automatic Cover Feeder With Indentation Design:

The machine incorporates a new intelligent indentation design, allowing for synchronized paper feed and four-indentation processes. This design enhances user-friendliness and facilitates the binding process.

2.Automatic Thickness Measurement and Speed Adjustment:

The machine can automatically measure the thickness of the book and adjust its running speed accordingly. This feature ensures optimal performance based on the specific requirements of each book, enhancing efficiency.

3.Automatic Pressure Adjustment

The machine automatically adjusts the pressure of the clip surface, optimizing the binding effect. This feature contributes to consistent and high-quality binding, reducing the workload on the operator.

4.High-Precision Binding:

The machine ensures high-precision binding, resulting in uniform and firm connections for each book. This not only improves the quality of the final product but also enhances its durability.

5.Industrial Synchronous Belt Transmission:

The machine utilizes an industrial synchronous belt transmission structure, providing a light and quiet operation with fast speed. This design contributes to a smooth and efficient binding process.

6.Automatic Finishing Glue Structure:

The addition of an automatic finishing glue structure addresses the issue of residual glue on the clamping surface platform, enhancing the aesthetics of the binding.

7.Cover Secondary Positioning Technology:

The machine features cover secondary positioning technology, addressing potential deviations in the book cover position to ensure accurate left and right positioning.

8.New Pre-Melt Groove Structure:

The pre-melt groove structure allows the operator to add glue without stopping the machine, improving overall binding efficiency.

9.PLC Integrated Module Control Circuit Design:

The PLC integrated module control circuit design enhances stability and reliability, contributing to the machine's longer life and consistent performance.

10.7-Inch Color Touch Screen Display:

The machine is equipped with a 7-inch color touch screen display, utilizing an ARM chip and color touch screen for powerful intelligent control and incorporating several self-test functions.

11.Frequency conversion technology

Having obtained the utility model patent for glue binder (Utility Model Patent No.: ZL201821725442.2).This innovative design enables easier binding, particularly suitable for large quantities for binding. The binding process is more efficient, ensuring precision and convenience, thereby providing users with a superior binding experience.