FRONT E4908T Programmable Electric Paper Cutter is a powerful device equipped with a 7-inch color touchscreen, allowing easy switching between manual, quick, and programmed modes for more convenient daily use.

Additionally, this machine features a unique blade depth adjustment function, eliminating the need for disassembly—blade depth can be easily adjusted externally, making the operation more convenient.

Its innovative exterior design not only adds aesthetic appeal but also includes conspicuous safety photocell operation indicators, ensuring safe and reliable operation."

Specifications

| Item Model | FRONT E4908T |

| Max. Cutting Size | 490*490mm/19. 29*19. 29 inch |

| Min. Cutting Size | 30mm/1. 18 inch |

| Cutting Thickness | 80mm/3. 14 inch |

| Cutting Accuracy | ±0. 3mm |

| Display | 7 inch Touch Screen |

| Clamp Mode | Electric |

| Pushing Paper Mode | Electric |

| Cutting Paper Mode | Electric |

| Electronic Knife Lock Structure | Optional |

| Power | 220V(110V)50Hz(60Hz); 1300W |

| Net Weight | 160kg/242. 5 lb |

| Dimensions | 770*1015*1250mm |

Competitive Advantage:

1.7-INCH DIAGONAL TOUCHSCREEN

FRONT E4908T features a 7-inch touchscreen.

Offering three different operating modes: manual, equal division, and programmable, meeting daily work requirements with easy switching and simple operation.

The user-friendly perspective makes the usage more comfortable and convenient.

2.MULTIPLE SAFETY PROTECTIONS

To provide comprehensive safety protection, the machine is equipped with an infrared safety protection design and standby alarm indicator function.

The rear cover's safety protection complies with CE standards, adding more safety assurance to the operation.

3.SLANTED BLADE PAPER CUTTING PATENT

Having obtained the utility model patent for slanted blade paper cutting (Utility Model Patent No.: ZL202021215296.6)

This innovative design enables easier cutting, particularly suitable for thick paper cutting. The cutting process is more efficient, ensuring precision and convenience, thereby providing users with a superior cutting experience.

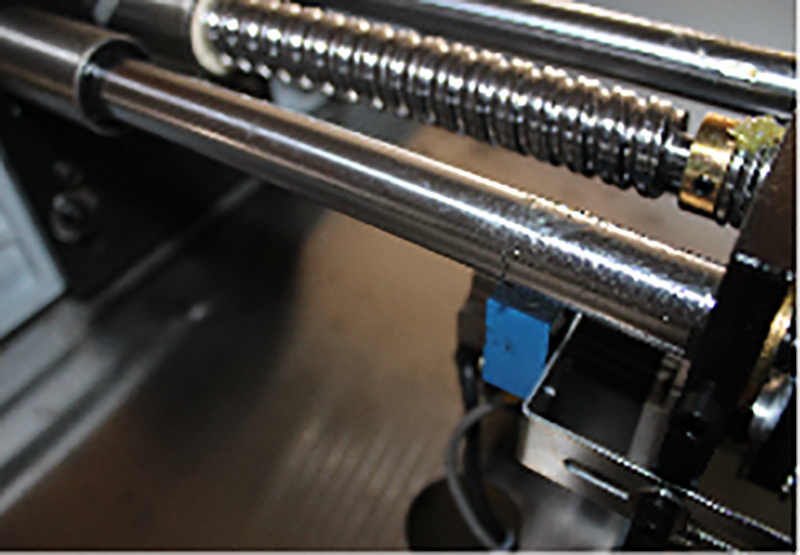

4.TOP-SUSPENDED BALL SCREW PAPER PUSHING STRUCTURE

The paper pushing platform is designed without grooves, combined with the top-suspended screw paper pushing technology, achieving a more stable and smooth paper pushing operation.

This innovative design not only enhances the stability of the machine but also significantly improves the precision of the cutting process, ensuring accurate cutting results.

4.PRECISION GEAR-DRIVEN PAPER CUTTING MOTOR

By utilizing a precision gear-driven paper cutting motor, the transmission efficiency of the cutting machine has been significantly improved.

Its high-efficiency transmission system not only ensures stability and reliability during operation but also greatly reduces the noise generated while the machine is running.

This type of motor operates at a very fast speed, robustly supporting the efficient execution of the cutting process.

5.THICKENED CAST MACHINE FRAME STRUCTURE

Thickened frame design and precision machining ensure cutting accuracy meets professional standards and provides outstanding durability.

The machine features a novel and stylish appearance, equipped with four casters for easy mobility.

6.Electronic Knife Lock Structure(Optional)

The advanced electronic knife lock structure effectively prevents the occurrence of slipping phenomenon during the cutting process and ensures safe operation.