One of the key components in bookbinding process is the adhesive you are going to use that can potentially affect everything from looks of a finished product, over time and strength. These include hot-melt and polyurethane reactive (PUR) glues, to name just a few, each of which come with its own unique properties and applications. This guide provides an overview of adhesive technologies and further reveals the differences between them, along with what applications one type is put to best use for - the top three scenarios; whom prefers which structural adhesives differ slightly as priorities change from project-to-project.

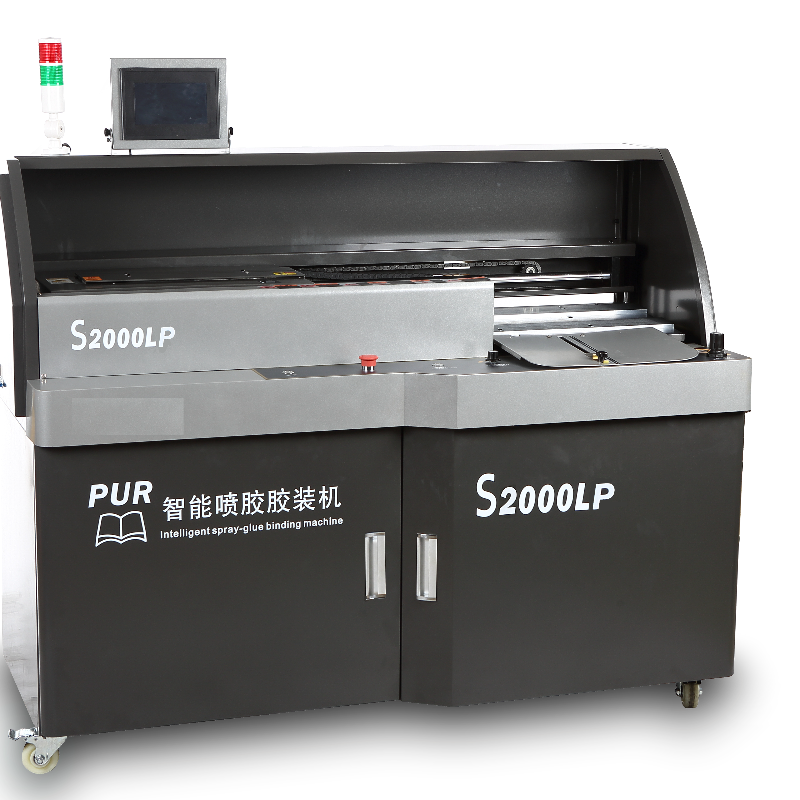

Hot-melt & PUR Glue (examples)

Hot melt adhesive, at it core function uses thermoplastic adhesives - meaning they are in a molten state when heated and can be molded easily. When they cool off, though, the melting chemicals stick back together and form a solid rod rapidly. Meanwhile, PUR glue is a moisture-curing adhesive that uses water in the air to react by creating permanent chemical bridges. And this difference is key - hot-melt glue cures through a physical change while PUR adhesive reacts chemically creating a... considerably stronger bond (and more flexible.)

Professional Hot-Melt Binding

Advantages; Hot-melt adhesive addition is favored in light of the fact that its simplicity and flexibility, With fast set up and curing times it is suited for on demand or short-run productions. The glue sets quickly, producing a complete glued book that can be safely "touched" seconds after it leaves the end of the M2000 and goes onto delivery conveyors - accelerating overall workflow efficiencies. Plus, hot-melt glue holds up for several types of heavy and lightweight paper so the aesthetic sells itself in that way! Many printing facilities choose perfect binding as their go-to because of the sheer convenience it offers, not to mention that its affordable in price.

Playing for KeepsReply: Bookbinding heeds the call of indestructibility and immortality.

PUR glue binding is the right choice for applications that require crabbing, long life cycles and durability And PUR glue for its bonds are less susceptible to page pull and still stay flexible after years of use, as opposed to hot-melt glues which tend become either brittle or weakened over time in extreme conditions. So that all this makes it ideal for library-quality books text publication and also various other high-mass magazines with substantial wear as well as use where long-lasting performance is essential. Of course, I most not forget that the PUR glue operates at a molecular level so it also reinforces natural life of bound materials and makes them more stable in case they are exposed to temperature changes or wet.

The Master of Hot Melt Adhesive Application

The science behind it and how you are using hot-melt adhesives is also important - the temperature, the pressure on that adhesive bed as its curing in terms of cooling rates. A stable temp is essential to ensure a thin, even spread of glue over the paper stock without softening it. Pressure from the application surface varies enough to let it slide past pages and creep into a spine without squashing any within. During quick and even cooling the mechanical bond power freezes immediately. Learn how to use these variables for the type of book you are using and thickness, this will give you perfect reult almost every time.

Ecological Aspect of PUR in the Bookbinding Industry

The eco-friendly advantages of PUR glue are a boon to an industry that is increasingly realizing its environmental footprint. While both can be proudly made with sustainability in mind, the superior physical properties of PURs produce up to a 5x longer lifespan than other reactive grades like hot-melt adhesives. Low-VOC (volatile organic compound) formulations in PUR glue technology have also just been developed to limit emissions during manufacturing and use for green publishing practices.

Overall, whether to choose the manual hot-melt glue and PUR perfect types would have a standard-off with between production output time versus book life in consideration of an environmental concern. Hot-melt glue can be faster and more pliable but for books that need to last the PUR adhesive is likely stronger, has wider mechanics stress resistance factor. Professionals who have knowledge about these seemingly permanent fixes will then be encouraged to add their two cents and make sure that the specifications of a project are met, which in turn works toward not just sustaining but building onto better policies for the publishing industry.

EN

EN

AR

AR

BG

BG

HR

HR

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

UR

UR

BN

BN

LA

LA

PA

PA

TA

TA

KK

KK

UZ

UZ

KY

KY