Technology has changed how books are made too - and yes, quick practice with better efficiency instead of tedious physical work. The restoration of this process in a much more illuminating fashion among numerous impressive innovations is automatic book binding equipment, signifying the order of our times and an advantageous answer for anyone with respect to commercial print-on-demand printing services. These machines have transformed book binding making the days of a manual hand-stitched spine doused with glue on every print much more elite and finely finished. In this article we will delve deeper into the Automatic binding technology and why it is any essential aspect in improving productivity, meeting current publication standards; provides unrivaled flexibility, have incorporated aspects that their products as well be more environmentally friendly while still maintaining cost-effective solutions for companies.

Quick and good is the mother of any successful print operation. It can bind hundreds to thousands of books per hour, a feat that has not been possible with manual methods and clearly demonstrating the power at which automatic book bonding machines work. These machines help in saving time byautomating the process of paper collation, application cover and spine. They also minimize human error leading to a perfect lineup on every single installation which is both very professional looking. This is where highly integrated software enters the equation - enabling services 100% of the time to adapt in real-time, right through any specific book size and format change with minimal interruptions.

The precision required to separate clear pages and feed stacks beneath impression rollers is achieved through automatic binding systems. This equipment have features like Straight corners and edges, squared covers which gives more reading pleasure so it raises publishers work quality. They are also available in various binding styles (almost like perfect binging, wire-o between coil) hence they can be tailor-made to cater to multiple market segments and provide sense of unity with your visual communication. Furthermore, as automatic binding machines are built to handle specialty materials such as hardcovers this gives printers the ability to offer higher end products that provide a massive boost in margins and gives competitive advantages.

This requires for adaptability and it performed a important role along with the frequent changing preferences of all these buyers, turning printing process in to even more real-time empowered publishers being extra agile on an increasingly swiftly transferring digital print-on-demand environment. The state-of-the-art automatic binding machines have modular constructions so transforming the setups to alter them in between various types of techniques for book-bonding and the formats are also simplified. But this versatility also measures it to bind almost all types of paper -- thin newsprint, stubby cardstock - and again the quality is steady high-bond. The digital controls can also be quickly set and changed to different jobs, which makes it possible for short-run production with little or no setup and changeover loss compared as mass productions. Not to mention, this agility allows publishers to pivot at scale with every new trend and customer feedback that arises.

So has sustainability moved to the top of bookbinders agendas, in line with all sectors getting more and more environmentally worried? Modern environmentally friendly automatic indoubt binding systems theangles that reveals and reduce waste, all their factors allow for Minimize our footprint on asprofitenvironment of human plant consumption Enterprise to minimize portletrentProcessEvent process. The intelligent mechanism for handling paper prevents small jams and wastage of consumables, leaving natural resources intact. Ecological Regulations Compatible Attracting equipment go along with bio-degradable and recycle-able gentle binders; for this reason these are generally noticed right for ecosystem friendly creating projects. The efficient motors along with low power consumption also minimize the carbon footprint. Publishers who use such machines not just save in operational efficiency but also show their commitment towards the planet.

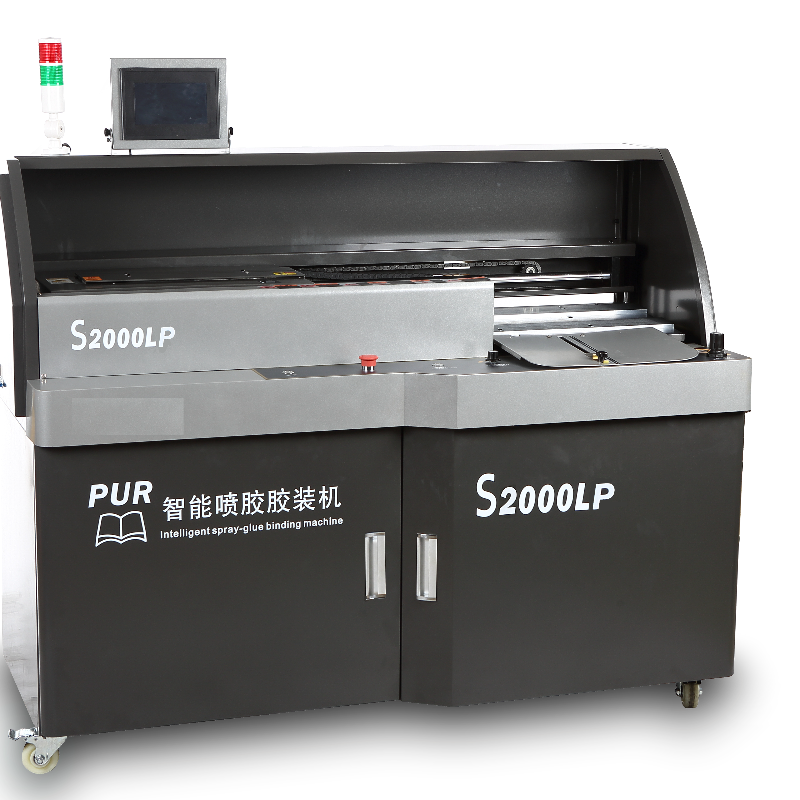

keeping company's business policy "focus innovation, creativity, trust" and promoting company's objective "creating first-class quality, establishing industry pioneer," company adheres ideals "honesty well as integrity constant progress." its nearly automatic book binding machine history company introduced range products including paper cutters, binding machines, laminators, folding machines, creasing machines.

automatic book binding machine facility business covers 50,000 square meters. It high-tech national enterprise integrating research, development, manufacturing, sales. equipment technologies skilled ensure high-quality products. team members armed extensive amount experiences, skills committed work commitment.

automatic book binding machine Daxiang Office Equipment Co., Ltd., major manufacturer post-printing machinery, one world's most respected companies. Established 2002, firm dedicated providing superior innovative post-processing solutions printing industry. With impressive technical knowledge well as modern production equipment an efficient management team, stands as significant manufacturing entity post-press digital industry well as office automation equipment.

team factory focused customers understands success organization based needs satisfaction automatic book binding machine. customers listened, production services optimized meet customer demands expectations.